Aluminum Welding Wire

Aluminum welding wire plays a crucial role in achieving seamless and high-quality aluminum welds. Aluminum, being a lightweight and corrosion-resistant metal, is widely used in various industries, including automotive, aerospace, construction, and manufacturing. However, welding aluminum can be a challenging task due to its unique properties. The use of the right aluminum welding wire is essential to ensure successful welding results.

One of the main challenges in aluminum welding is the formation of oxide layers on the metal’s surface. Aluminum readily reacts with oxygen in the air, resulting in the formation of aluminum oxide. This oxide layer acts as a barrier during welding, preventing proper fusion between the base metal and the filler material. To overcome this challenge, aluminum welding wire is specially designed with a flux or coating that helps remove the oxide layer and promotes better weld penetration.

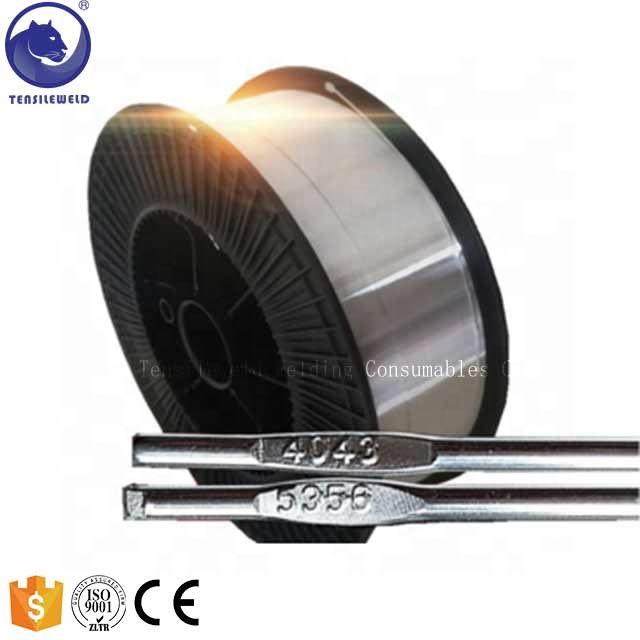

Another critical factor in aluminum welding is the choice of filler material. Aluminum welding wire is available in various alloys, each with its specific properties and applications. The choice of the right alloy depends on the base metal and the desired weld characteristics. Common aluminum welding wire alloys include 4043, 5356, and 5556. These alloys offer excellent corrosion resistance, strength, and weldability, making them suitable for a wide range of aluminum welding applications.

The diameter of the aluminum welding wire also affects the welding process. Thinner wires, such as 0.8mm or 1.0mm, are typically used for thin aluminum sheets or light-gauge materials, while thicker wires, such as 1.2mm or 1.6mm, are suitable for thicker aluminum sections or heavy-duty applications. The proper selection of wire diameter ensures optimal heat distribution and weld bead formation.

Furthermore, the welding process itself plays a crucial role in achieving successful aluminum welds. Aluminum welding typically requires the use of a specialized welding technique called Tungsten Inert Gas (TIG) welding or Gas Metal Arc Welding (GMAW). These processes provide better control over heat input, arc stability, and weld puddle manipulation, resulting in high-quality and defect-free welds.

In conclusion, aluminum welding wire is a vital component in the aluminum welding process. Its unique flux or coating helps remove the oxide layer, promoting proper fusion and penetration. The choice of the right alloy and wire diameter ensures desired weld characteristics and optimal heat distribution. When combined with proper welding techniques, aluminum welding wire enables seamless and high-quality aluminum welds, making it an indispensable tool for various industries.