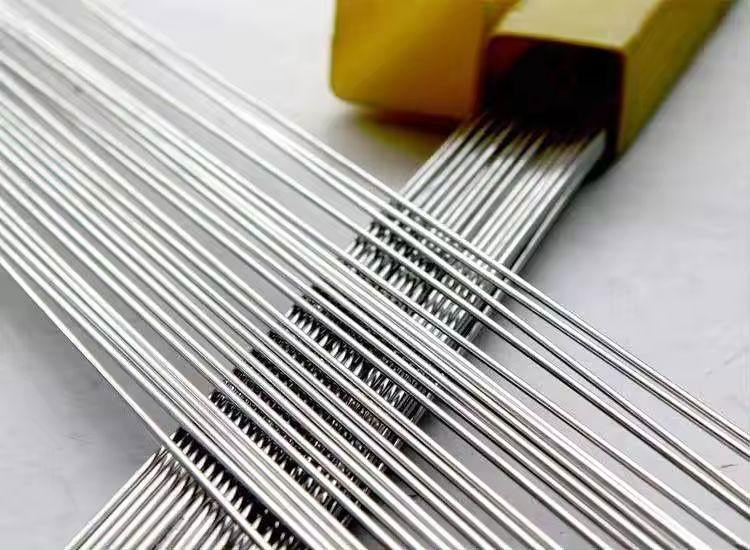

Classification of Aluminum Welding Wires

Aluminum welding wires are classified based on their chemical composition and intended application. One common type of aluminum welding wire is ER1100, which is widely used in various industries for its excellent welding properties.

ER1100 is a pure aluminum welding wire with a minimum aluminum content of 99%. It is suitable for welding aluminum alloys with similar composition and is commonly used in applications where high strength and corrosion resistance are required. ER1100 welding wire is often used in industries such as aerospace, automotive, and marine.

In addition to ER1100, there are other types of aluminum welding wires available, each with its own unique properties and applications. Some examples include ER4043, ER5356, and ER5183, which are designed for specific aluminum alloys and welding processes.

When selecting an aluminum welding wire, it is important to consider factors such as the base metal composition, welding technique, and desired mechanical properties. Choosing the right welding wire can help ensure a strong and durable weld, as well as improve the overall efficiency of the welding process.

In conclusion, aluminum welding wires are classified based on their chemical composition and intended application. ER1100 is a pure aluminum welding wire commonly used for welding aluminum alloys with similar composition. By understanding the different types of aluminum welding wires available, welders can make informed decisions to achieve high-quality welds in their projects.