Flap Discs: A Versatile Tool for Various Applications

Flap discs are abrasive tools that are widely used in various industries and applications. These discs consist of multiple overlapping flaps made of abrasive material, such as aluminum oxide or zirconia alumina, which are adhered to a backing plate. The flaps are angled in a way that allows them to gradually wear down during use, exposing fresh abrasive material and ensuring consistent performance.

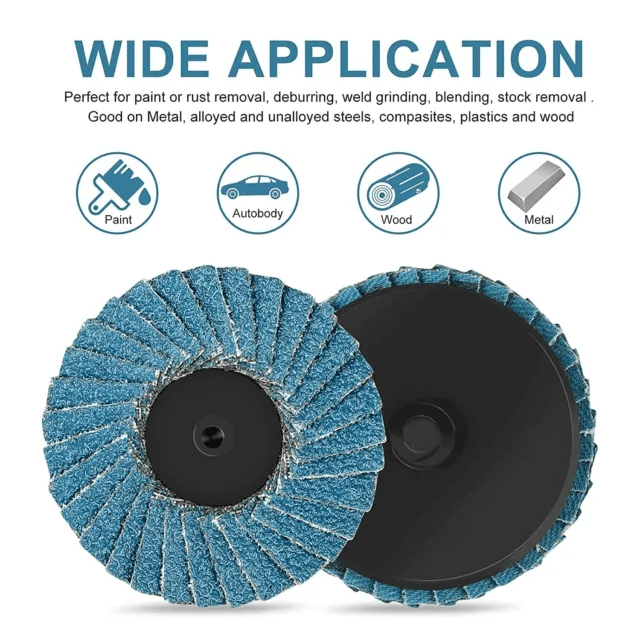

One of the primary uses of flap discs is in metal fabrication and finishing. They are highly effective in removing weld seams, blending surfaces, and providing a smooth finish. Whether you are working with steel, stainless steel, or other metals, flap discs can quickly and efficiently remove material while leaving a clean and polished surface.

Flap discs are also extensively used in woodworking applications. They are excellent for shaping and smoothing wood surfaces, removing paint or varnish, and preparing surfaces for painting or staining. With their versatility, flap discs can be used on both soft and hardwoods, making them an essential tool for carpenters, furniture makers, and DIY enthusiasts.

In addition to metal and wood, flap discs can be used on a variety of other materials, including plastic and fiberglass. They are ideal for removing rust, corrosion, and old coatings from surfaces, making them suitable for automotive repairs and restoration projects. The flexibility of flap discs allows them to conform to different shapes and contours, enabling precise and detailed work.

Another advantage of flap discs is their long lifespan. Compared to other abrasive tools, flap discs tend to last longer due to the gradual wear-down of the flaps. This not only saves money but also reduces downtime for replacing worn-out discs.

When using flap discs, it is important to consider the grit size. Coarser grits, such as 40 or 60, are suitable for heavy material removal, while finer grits, such as 120 or 180, are better for smoothing and finishing. It is also crucial to use the appropriate flap disc for the intended application and to follow safety guidelines, including wearing protective eyewear and gloves.

In conclusion, flap discs are versatile tools with numerous applications. Whether you are working with metal, wood, or other materials, flap discs can help you achieve efficient material removal, surface blending, and finishing. With their durability and flexibility, they are a valuable asset in various industries and a must-have for anyone involved in fabrication, construction, or DIY projects.