Guide for use of water-cooled argon arc welders

Guide for use of water-cooled argon arc welders

Nickel-based alloy is a very important corrosion-resistant metal material because of its good properties of resistance to reactive gases, abrasion and acid medium corrosion, high strength, good plasticity, cold and hot deformation, processing and forming, and weldability.

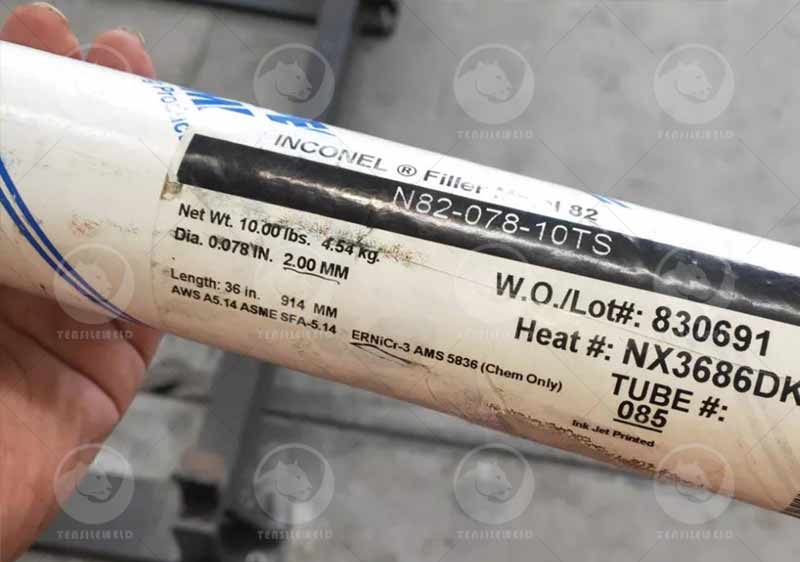

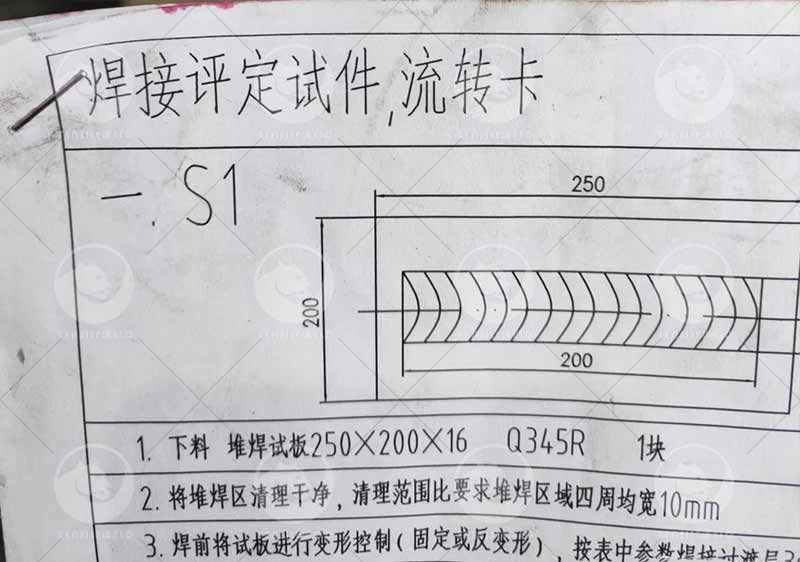

In surfacing application, carbon steel or stainless steel can be surfacing with a layer of nickel-based metal as the medium layer, making it have the advantages of two metals. This kind of welding material is completely different from common alloy elements. Different welding methods should be adopted in welding.

Due to the different physical properties of metals in surfacing welding, the nickel-based alloy welding pool is very viscous and has a shallow melting depth. Increasing the welding current cannot obviously improve the fluidity of metals and increase the melting depth.

Different from the concave weld bead usually formed by stainless steel, the weld bead surface of nickel-based alloy is obviously convex.

In order to prevent crystallization cracking, especially in the first layer of weld root, the welding metal can be filled with small current to eliminate it.

When argon arc welding is applied, the welding material should not be directly immersed in the molten pool. The welding material should be positioned in front of the tungsten electrode and fed while melting. The end part of the welding material is always under argon protection.

Nickel-based welding materials have poor fluidity, unfavorable excessive current, slow welding speed, and should be carefully controlled during welding.

During welding, whether it is interlayer welding or cover welding, pay attention to argon protection during welding to prevent oxidation of welding parts.

Cold work hardening tendency of different materials is different, for example, nickel-based alloy has 1~2 times higher cold work hardening tendency than stainless steel, so welding is easy to bend if it is not controlled carefully.

The strength of two dissimilar steels is different in overlaying welding. Pay attention to stress cracking at the root after welding.

Nickel-based alloy weld metal is not as easy to wet and expand as steel weld metal. Even if the welding current is increased, the fluidity of weld metal cannot be improved, but it plays a harmful role. If the welding current exceeds the recommended range, it will not only overheat the molten pool, increase the sensitivity to thermal cracks, coarsen the crystal grains and reduce the corrosion resistance, but also evaporate the deoxidizer in the weld metal and cause pores.

During SMAW, excessive welding current will also overheat the electrode and cause the coating to fall off, thus losing its protective effect. Due to poor fluidity of weld metal, it is not easy to flow to both sides of the weld. In order to obtain good weld formation, swing process is sometimes used. However, this swing is a small swing, and the swing distance does not exceed 3 times the diameter of the welding wire or electrode. Sometimes defects are found in SMAW even if the swing process is used.

Defects mainly include undercut and unfused edge. In order to eliminate these defects, when swinging to the limit position of each side in welding, pause a little so as to allow sufficient time for the melted weld metal to fully fuse with the base metal and fill the undercut. Another important technological measure to be adopted in SMAW is that the welding arc should be as short as possible.

During the welding process, the inherent characteristics of the electrode nickel-based alloy determine that its molten iron penetration is relatively shallow. Simply adjusting the welding parameters cannot solve this problem.

According to repeated tests, the method to overcome the depth of melting is to modify the traditional groove form, and the angle of groove position is more appropriate from 40 degrees to 65 degrees.

The welding of nickel-based materials is more strict than that of carbon steel and stainless steel on the surface of the weld. When nickel-based materials are welded, they must be welded into a convex weld bead. Most cases of nickel-based material welding cracking are caused by uneven strength caused by concave weld bead.

The interlayer temperature in the welding process of nickel-based surfacing materials should not be too high, and it is generally required to be below 100℃. Generally, preheating and post-heat treatment are not required for welding nickel-based alloy materials.