Types And Applications Of Titanium Wires

Pure titanium is a silver-white metal with many excellent properties. The density of titanium is 4.54g/cm3, which is 43% lighter than steel and slightly heavier than the prestigious light metal magnesium. The mechanical strength is about the same as that of steel, twice that of aluminum and five times that of magnesium. Titanium is resistant to high temperatures, with a melting point of 1942K, which is nearly 1000K higher than gold and nearly 500K higher than steel.

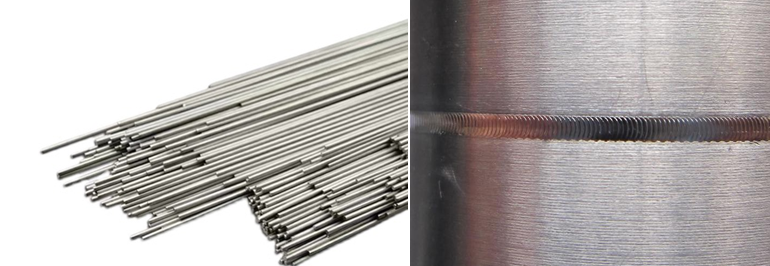

The Types Of Titanium Wire

Titanium wire is divided into: titanium wire, titanium alloy wire, pure titanium glasses wire, titanium straight wire, pure titanium wire, titanium welding wire, titanium hanging wire, titanium coil wire, titanium bright wire, medical titanium wire, titanium nickel alloy wire. Different types of titanium wire have different uses. For example, pure titanium glasses wire is mainly used for making glasses holders, titanium hanging wire is used for hanging weight, and titanium nickel alloy wire is commonly used as a memory alloy material.

The Applications Of Titanium Wire

Titanium wire also perfectly inherits the advantages of titanium and titanium alloys, with a series of excellent characteristics such as good corrosion resistance, high specific strength, non-magnetic, high biocompatibility, low impedance to ultrasound and good shape memory function.

Therefore, titanium and titanium alloy wires are widely used in many fields such as military industry, glasses, earrings, headwear, electroplating hangers, welding wires, aerospace, petrochemical, medical and health, automotive, construction, and sports and leisure products.

And in recent years, due to the continuous development of titanium wire industry, the variety of titanium wire has become increasingly diverse, which makes titanium wire more and more widely used in high-performance industrial supplies and consumer products.

1. At present, more than 80% of titanium and titanium alloy wires are used as welding wires, such as welding of various titanium equipment, welding pipes, repair welding of turbine discs and blades of aircraft jet engines, and welding of casings.

2. In the electroplating and water treatment industries, titanium and titanium alloy wires are used to manufacture various electrodes.

In short, with the development of the economy, the demand for titanium and titanium alloy wires is increasing. At present, titanium and titanium alloy wires are in short supply, and their development potential is very large.